The amount of water supplied to the dryer over a period of time is measured. Selected dryer type so the set of design param-eters or assumptions is fulfilledthis is the com-mon design problem.

Cfd Modeling Of Heat Transfer And Flow Field In Spin Flash Drying Process Request Pdf

Spin flash dryer design calculation Coffin nails are getting to be the most well liked manicure craze at the moment and that is likely nowhere fastBlack appears ideal with any color.

. Stokes drag gravity-Buoyancy LV perm V vK ρ ρ ρ FRv vis d d6πμ 4 3 gLV d3 F ρ ρπg R 14 22 3 drag vis drag g D D V d L V d23 F FF F C R vπ ρρρπg R F vis F drag F g 1 2 drag D V d2 FCAv ρ 8 3 d D gR K C F drag visF. An allotted drying time between 217 and 254 hours would require a drying air temperature between 290 and 293 Kelvin and a drying air velocity of 03 meters per second. Rotary Dryer Calculation Volume calculation.

Ad Get Flash Dryers Equipment Within 24 Hours Or Consult With Industry Experts. Flash Dryer Design Calculations Flash dryer design calculations Portray the midnight with dark midnight blue along with some smoky grey in excess of it portraying clouds with these stars peeping out and utilizing studs to make constellations is simply so excellent. 25 Clearance between scrapper blades and cylindrical shell R.

4 4 V Therefore D AD π π v perm ρV Demisters should take care of 4 or less of the 5. Screenprinting Supplies Screens. Whenever possible to apply heat direct to the material to be dried Rotary Dryers of the Direct Heating Design are used.

FLASH DRUM DESIGN ChE 4253 - Design I D related to vapor velocity. Has a far-reaching influence on methods of solving the model. With experimental data and the influence of the fric-tion factor on the pressure gas and particle.

Horizontal Dryer 1 Parameter Unit Initial Reduced Combustion Air Net Temperature 0C 88 88 O2 199 197 CO ppm 22 24 Combustion Efficiency 379 447 CO2 06 07 Flue Gas Temperature 0C 119 120 Ambient Temperature 0C 307 31 Excess Air 1990 1642 Pressure mbar 004 005 Table 6. Rotary Dryer Kiln. For evaporating moisture from concentrates or other products from plant operations Rotary Dryers are designed and constructed for high efficiency and economy in fuel consumption.

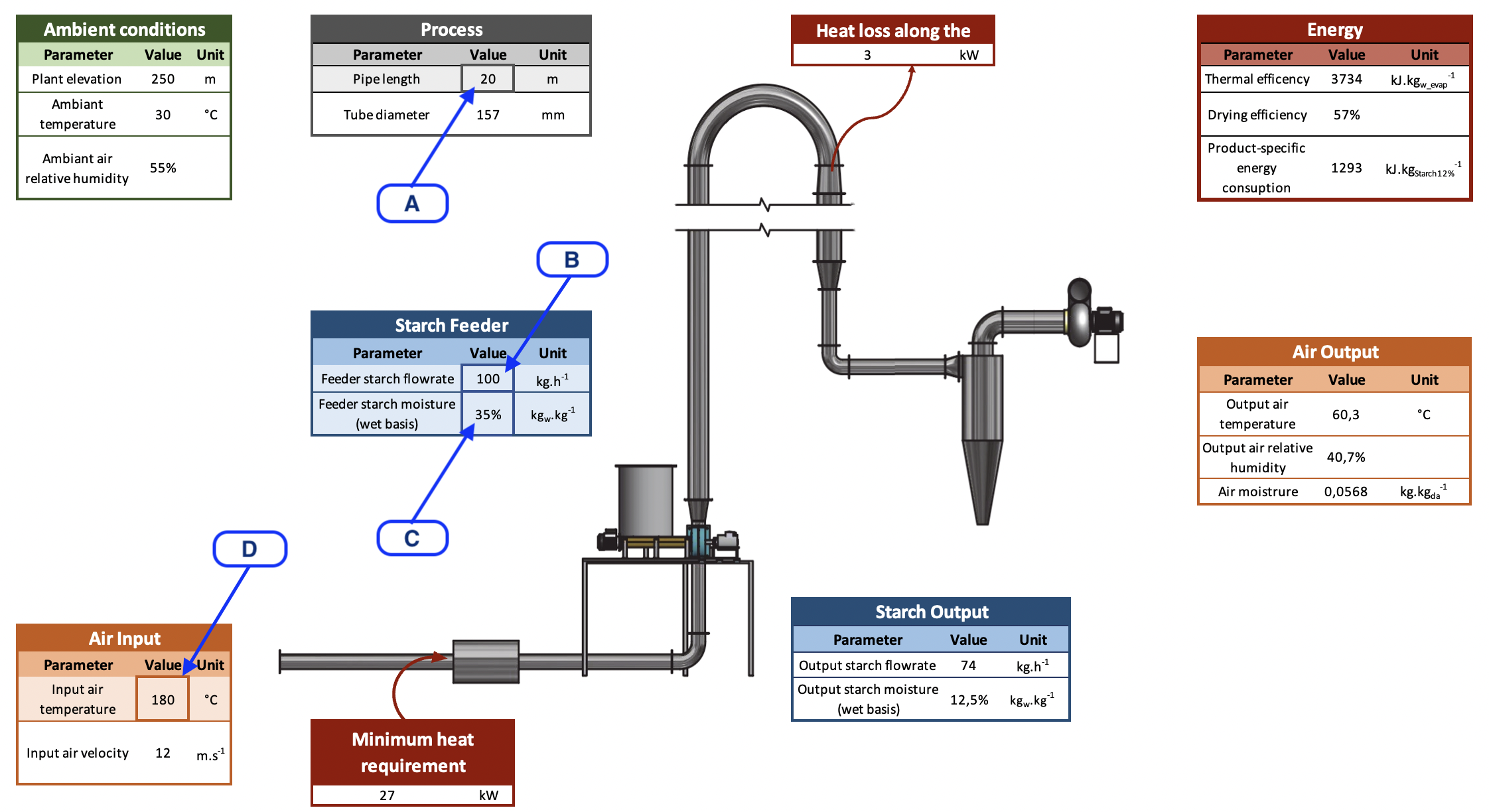

Calculation of the quantity of water to be evaporated is explained below with a sample calculation. Design basis The following were the physico-chemical properties of cassava starch used as input variables to determine parameters of interest necessary for the design of a column flash drying unit. Heat transfer area of ATFD A.

Of the numerical calculations were partially compared. The dryer senergy usemust also beseen in the context of the complete process and indeed of the site as a whole. We Make Sure Premium Quality With Low PricesVevor Official SiteFree Shipping For You.

For example to dry 20000 lbshr 9000 kgh of a 30 solidswater slurry to 05 moisture the spray dryer would have an approximate diameter of 30 ft. Provided Rotary Dryer dimensionφ2020m. One key tool is pinch analysis Section 142 which shows the temperatures at which the dryer heat load is required and where heat can be recovered from the.

Solids bulk density BD. The spray dryer usually has a greater amount of water to remove by thermal methods than other types. 163 Design of Flash Dryers.

Horizontal Dryer 2 Parameter Unit Initial Net. A corresponding equation will have to be dX written for yet another phase gaseous and the equa- WS X1 u0002 WS X2 u0002 wD A ¼ mS 32 dt tions will be coupled by the drying rate expression. The dryer is operated on water under constant t1 and t2 for at least 1 hour to obtain stable conditions.

They are inherently cocurrent dryers with the hottest air contacting the wettest product. Radius r d2. The results prove that the dryer is most efficient when the dryer runs at 370 Kelvin and 03 meters per second when the allotted drying time is less than 217 hours.

Mechanical drives and other general uses. Flv WL ρ L were obtained V V fitting experimental data. Ad We Make Sure Premium Quality With Low PricesVevor Official SiteFree Shipping For You.

However it doesnt ensure it is any less attractive. So we have to decide the feed rate now. In drying of wet solids the following main factors which essentially are used in process design calculation of dryers should be defined in accordance with mass and heat transfer principles process conditions and drying behavior.

60 kg of wet product contains 60 x 055 kg water 33 kg moisture and. The most suitable way is to measure the level difference h in a cylindrical feed tank of diameter D. 5 Sqm Diameter of ATFD d.

This phase being dried in kgs this equation reads. Flash drying is a continuous process with the dryer being either directly or indirectly fired. Dryer calculations unless it can be converted to the.

Thus W ρ K e A B ln Flv C ln Flv 2 d ln Flv 3 E ln Flv 4. Ad The Best Selection of Eco-Friendly. Feed moisture content 6875 wet basis Carbohydrate content of cassava starch 2890 Protein content of cassava starch 175.

ChE 4253 - Design I f FLASH DRUM DESIGN 1 hV 36 diameter of feedline 2 Who came up with this rule and why. 04 KgL Solids concentration C. Mechanism prior to design work is strongly recommended.

If the throughput of the dryer is 60 kg of wet product per hour drying it from 55 moisture to 10 moisture the heat requirement is. Spin Flash Dryer Design Calculation. They operate at inlet temperatures varying from ambient dehumidified air for sensitive products to more than 1100 o F 600 o C for robust products.

Flash Dryer Design Tools Rtb Scaling Flash Drying

Schematic Of A Simple Flash Dryer Download Scientific Diagram

4 Spin Flash Dryer From Devahastin S Ed Mujumdar S Practical Download Scientific Diagram

Pdf 6 Pneumatic And Flash Drying

1 Simple Flash Drying System Download Scientific Diagram

Flash Dryer Design Tools Rtb Scaling Flash Drying

Schematic Diagram Of A Flash Dryer Download Scientific Diagram

0 comments

Post a Comment